The new technology developed by scientists at Lviv Polytechnic is accessible and can be implemented by Ukrainian manufacturers of specialized insulated glass units quickly and at minimal cost.

The technology, developed by a research team led by Professor Serhiy Varvarenko from the Department of Organic Chemistry at the Institute of Chemistry and Chemical Technologies, involves creating a liquid filling composition for the interstitial space in insulated glass units. This composition, when sealed and subjected to thermal treatment, forms a transparent hybrid polymer-mineral hydrogel in multilayer glass, as reported by the university's press service.

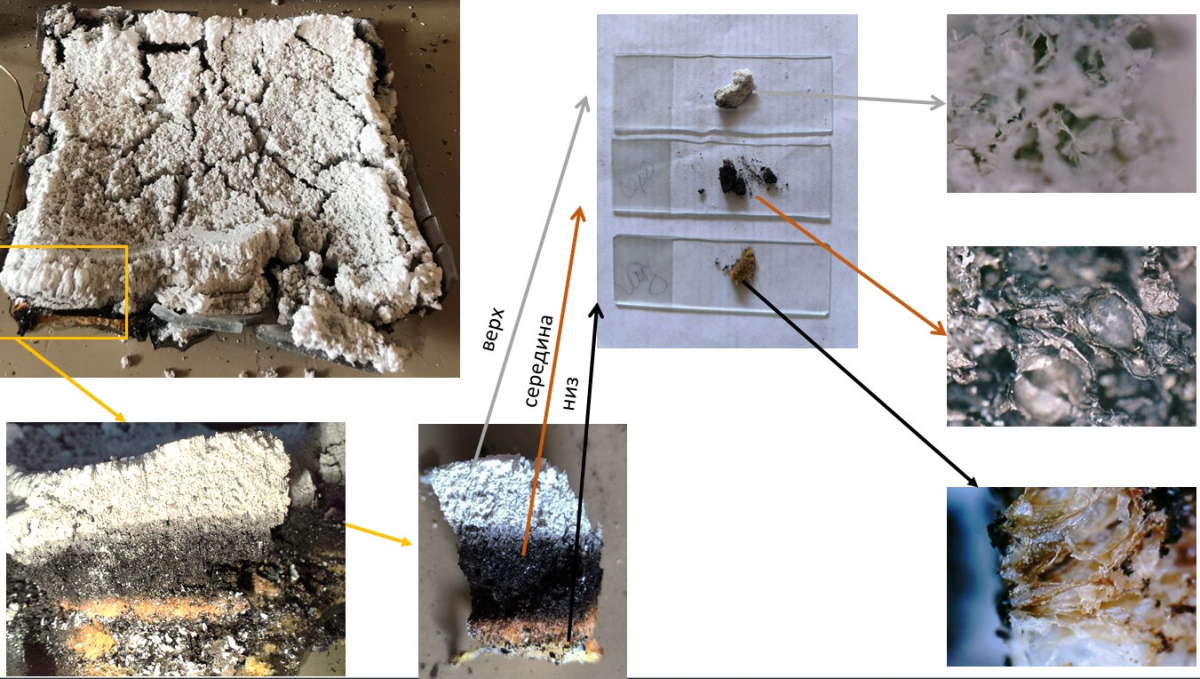

In the event of an emergency, such as a fire, the hydrogel expands into a foam when exposed to high temperatures. At temperatures of 150–250°C, the hydrogel transforms into a porous, opaque protective material, maintaining the integrity of the glass construction without holes or cracks and preserving its thermal insulation properties.

"Typically, such glass is ordered from abroad, so the emergence of a domestic producer of fire-resistant glass is necessary and relevant for both manufacturers and consumers. Establishing production in Ukraine will enable the manufacture of this glass in the required quantities, sizes, and relatively short timeframes. Additionally, minimal logistics costs are an advantage, as all components for the hydrogel composition are available in Ukraine. This significantly reduces production costs and makes the product more accessible. Testing of research batches of fire-resistant glass has demonstrated its advantages and competitive price compared to available analogs," noted Professor Serhiy Varvarenko.

The project "Development of Hydrogel Composition for Fire-Resistant Insulated Glass Units and Technology for Its Production" received grant support from the National Research Foundation of Ukraine.