The Kyiv-based company 3D Metal Tech designs and prints titanium implants for patients with severe bone tissue injuries — often these are military personnel wounded on the front lines. Using 3D printing and CT scans, the team creates fully personalized solutions tailored to each specific case.

"The level of defects is extremely complex — sometimes it’s impossible to use standard solutions. That’s why we design custom implants based on CT images," bioengineer Artem Tsurkan told dev.ua.

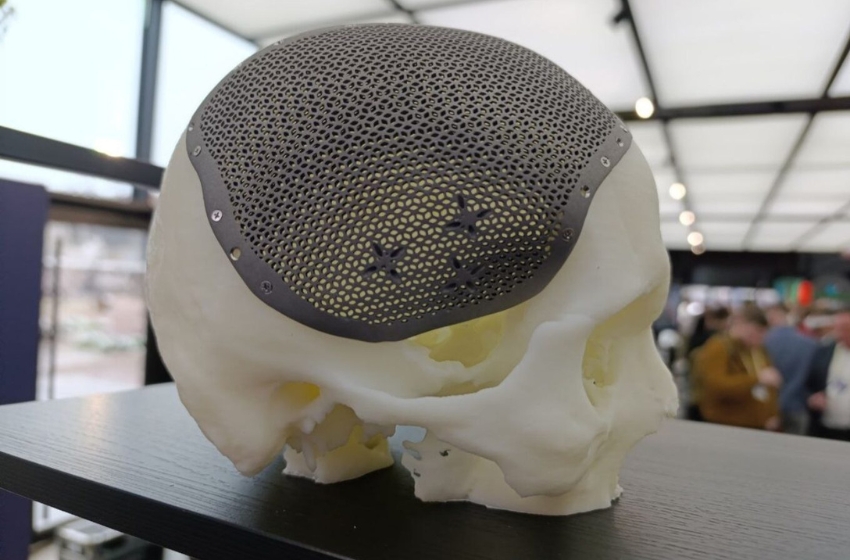

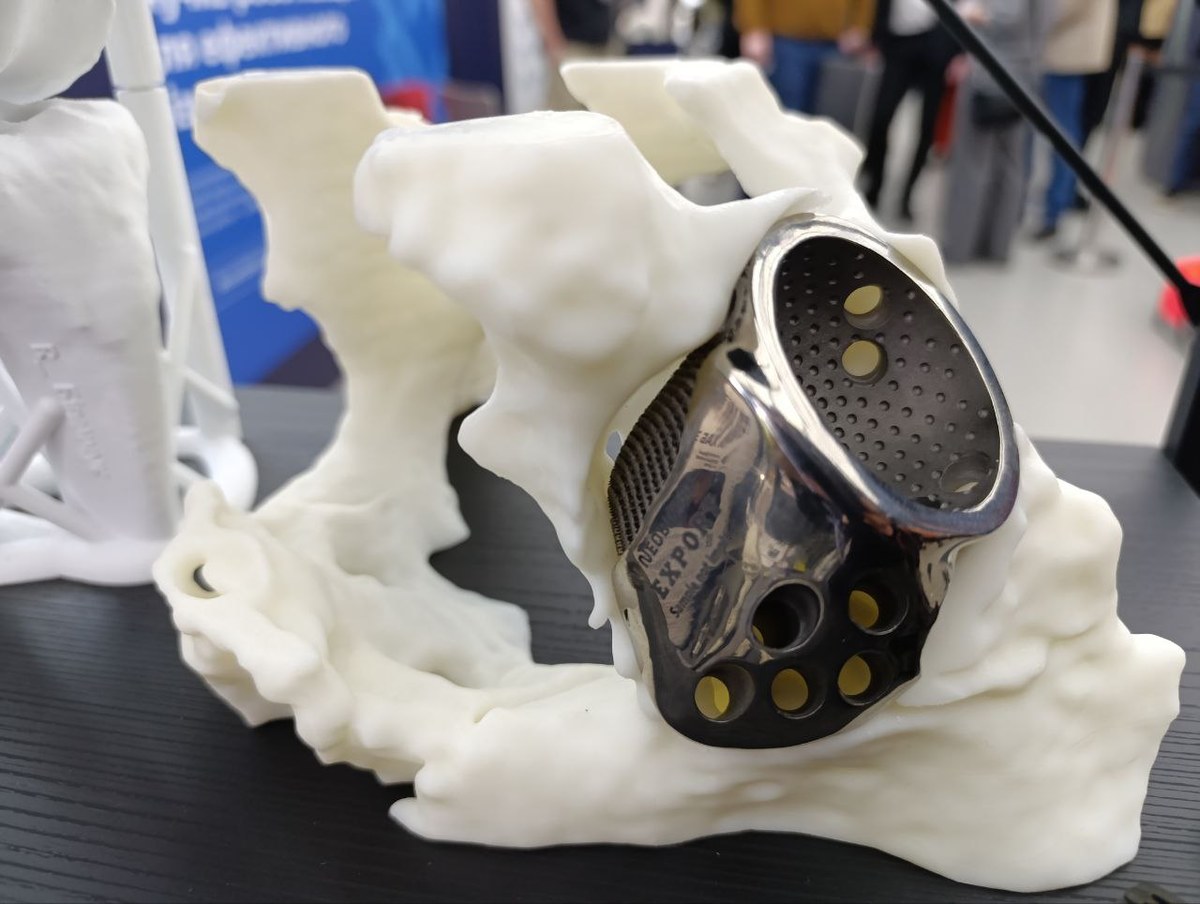

The implants serve a variety of purposes — from hip joint cups and cranial plates to dental implants. Work with patients takes place either directly or through clinics and doctors. The process begins with design, doctor approval, printing a plastic model for testing, and only then printing the final titanium version.

The company owns a 3D printer capable of producing fairly large titanium parts — one of the few such devices available in Ukraine. The machine costs about $750,000 and can print titanium components up to 30×30 cm in size.

Since the beginning of Russia’s full-scale invasion, the team has produced over 2,000 custom implants, mostly for military personnel.

For wounded soldiers, this service is completely free, with the costs covered by charitable foundations. For civilians, the cost of an implant — for example, a cranial plate — ranges from €1,000 to €2,000.

3D Metal Tech now employs around 25 people, including bioengineers responsible for implant development. The team is actively growing and currently hiring new specialists.