The ground-breaking technology developed by an Odessa-based firm A.D.A.M. Bioprinting will enter the medical devices and implants market in the US which is estimated to be worth $ 1.8 billion (and orthopedic implants market is at $ 47 billion).

A.D.A.M. was founded in 2018 by 3D printing company Kwambio (Odessa) and WeFund Ventures (Tallinn). The initial vision of the company was to create a carshop-like infrastructure where any part of the human body can be treated like a replaceable part. A.D.A.M. team decided to start the project with a focus on bone implants and have developed proprietary 3D printing technology and material composites for the implants. The first prototypes passed pre-clinical trials in wistar rats. Successful results of the trials allowed A.D.A.M. to file the Q-Submission to the FDA. In their response, the FDA confirmed A.D.A.M. biopolymer and bioceramic bone implants' 510(k) eligibility. Concurrently, the company moved its HQs to the Technology Incubation Programme at University of Connecticut.

A.D.A.M. plans to complete the animal studies, required by the FDA, in 2021. Next, the company aims to receive regulatory clearance for bone implants and begin the sales stage in 2022.

Bone implants, however, are just the beginning - in the years to come A.D.A.M. aims to launch R&D of blood vessel, heart valve and bronchial implants. A personalised bone, just like yours. With no toxic, allergic, and teratogenic effects.

These results confirm that the implants are working as designed, and the Industry Standards Organization agrees. A.D.A.M.’s implants received ISO 10993-10: 2010, EN ISO 10993-11: 2015, ISO 10993-5: 2015 and ISO 11137-1: 2018 testing certifications. These certifications demonstrate the devices do not irritate skin, result in system toxicity or cytotoxicity, and are sterile after radiation treatment.

In August, 2020, FDA confirmed 510(k) eligibility for A.D.A.M. biopolymer and bioceramic bone implants. No human trials are required. FDA clearance is expected in 2022.

A.D.A.M. project is the way to:

- free people from their bodies;

- create infrastructure, which can work as the repair shops;

- turn transplantations from something outstanding to an ordinary process.

Through it’s activities A.D.A.M. aims to help people to get affordable way to save their lives.

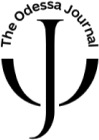

Implant modeling

Patients may upload and securely store their MRI and CAT scans on the digital platform. Should the patient be in need of the bone implant, certified clinicians would be able to use the platform to create a 3D model of the implant based directly on the patient's medical data.

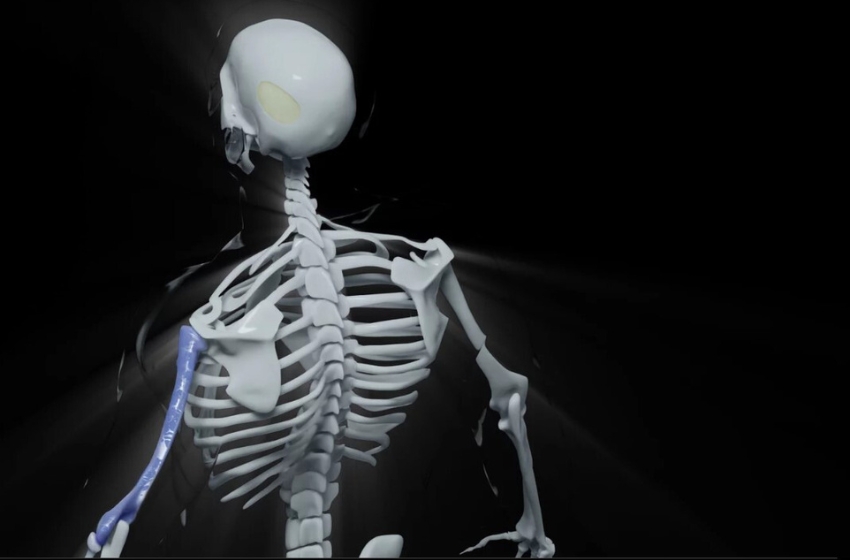

Implant production

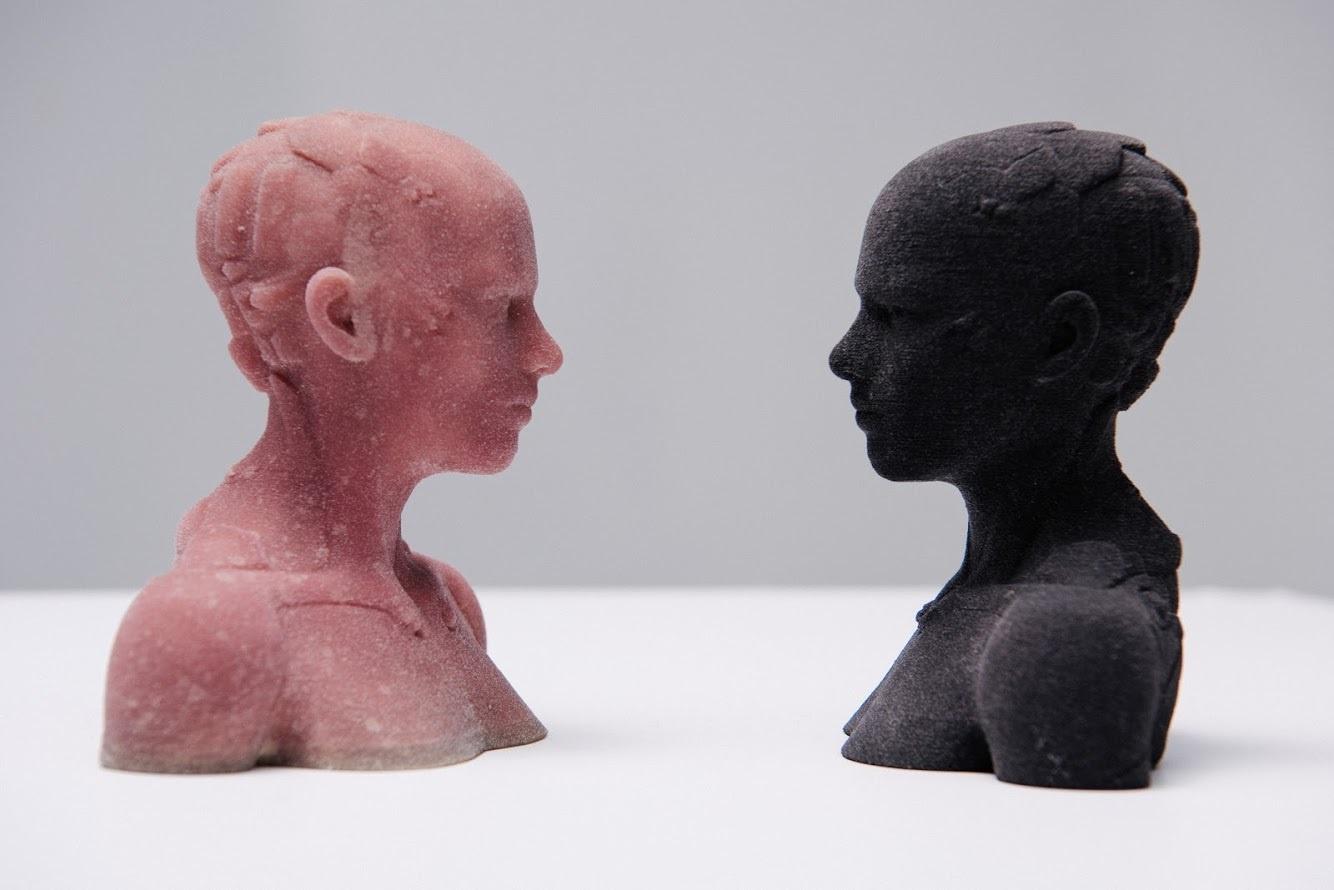

The resulting 3D model of the patient-specific bone implant will be used for its subsequent production using A.D.A.M. proprietary 3D printers. Printing may take place at A.D.A.M. or directly on site, subject to the medical institution's preferences.

Overall production time will take up to 24 hours, which is substantially faster compared to the existing alternatives. At the same time, use of 3D-printing technology and A.D.A.M. material composites results in a lower cost of production than for titanium or PEEK-based implants.

Implantation

The project will help medical professionals through a developed set of Quality Management System procedures, which will ensure safety, efficacy and quality of the implant.

Medical professionals will receive a sterilized 3D-printed bone implant ready for use in surgery.

Recovery

The bone implants are biodegradable. They stimulate osteogenesis and are fully replaced by the bone tissue over time. Therefore, there is no need for reoperation to extract implant elements.