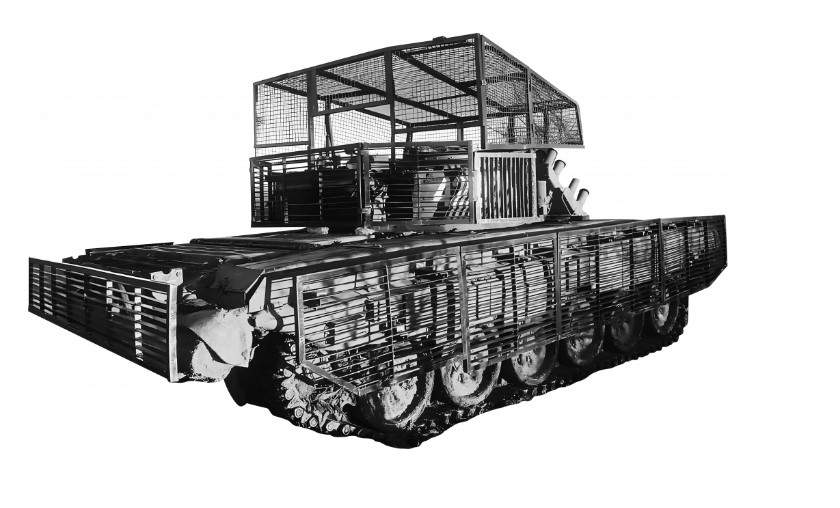

Ukrainian Leopard tanks are receiving enhanced protection through the development of steel grid screens initiated by Rinat Akhmetov's "Steel Front." These screens are manufactured by Metinvest at its secret facilities.

According to company's press service, the screens are designed to protect military equipment and soldiers' lives from FPV drones, which remain a significant threat on the battlefield. The cost of the structure is approximately $20,000, which is just 0.3% of the actual Leopard tank price, around $6 million. Additionally, the Armed Forces of Ukraine receive these steel screens free of charge.

Unlike Russian "improvised" protections, Ukrainian screens provide defense without compromising the maneuverability and combat effectiveness of the equipment.

"The primary task of the screens is to protect the equipment without any limitations on functionality, safety for the crew, or maneuverability. Therefore, the screens are designed in such a way that they do not affect the functional component. Otherwise, their use would be unjustified and unnecessary," said Oleksandr Myronenko, the operational director of the Metinvest Group.

These structures are already used on Soviet T-72 tanks, Ukrainian T-64s, American M1 Abrams tanks, and BMP Bradley vehicles. The screens are installed at the Ukrainian Armed Forces' own repair bases, after which the vehicles equipped with additional protection are sent to the front lines. A team of 10-12 people takes about 12 hours to mount one screen.

"The soldiers note that the survivability of the equipment increases by 30-40%. We have real cases when vehicles were stopped on the battlefield, but thanks to our screen, the crew remained alive and unharmed. They managed to get out, and the vehicle was later taken away for repair," Myronenko added.

The Leopard is a German tank considered one of the best in the world due to its maneuverability, fuel efficiency, and ease of maintenance.

The "Steel Front" initiative led by Rinat Akhmetov has actively supported Ukrainian military forces since the start of the full-scale war. Within this project, armor plates, mobile shelters, and other products for the Armed Forces of Ukraine are being manufactured.

A historical overview –The evolution of screen protection

The idea of installing screens to protect military equipment is not new. Examples of their use date back to the First World War. Faced with the threat of German submarines, the British Royal Navy introduced the use of anti-torpedo nets. These massive steel nets were hung on the sides of large ships, particularly battleships and cruisers.

During the Second World War, screens were used to protect ground vehicles. In 1943, the German army introduced Schürzen, steel screens mounted on the sides of tanks. These “skirts,” as they were unofficially called, were designed to protect against anti-tank rifles and cumulative shells.

The Soviet Union also actively experimented with protective screens. Screens for KV and T-34 tanks were widely used, for example, during the Battle of Kursk in 1943.

During the Cold War, the development of protective technologies continued. The US experimented with composite screens for M60 tanks, which combined steel and ceramics to increase protection against cumulative ammunition.

In modern conflicts, the interest in protective screens was revived in the early 2000s, during the wars in Iraq and Afghanistan. The US Army developed the TUSK (Tank Urban Survival Kit) system for M1 Abrams tanks, which included lattice screens.

The British Army has also adapted its Challenger 2 tanks by introducing the Barracuda system. It not only provided physical protection, but also had camouflage properties in the infrared spectrum.

Modern developments in the field of military equipment protection include active protection systems that combine sensors, computing systems and physical screens.

Metinvest and Steel Front are learning from the close examination of the experience of other armies around the world to improve the products that protect Ukrainian soldiers. But the most valuable insights come from the front line, from the AFU, and these are helping to constantly improve the “chain mail” for the precious tanks that protect our even more precious defenders.